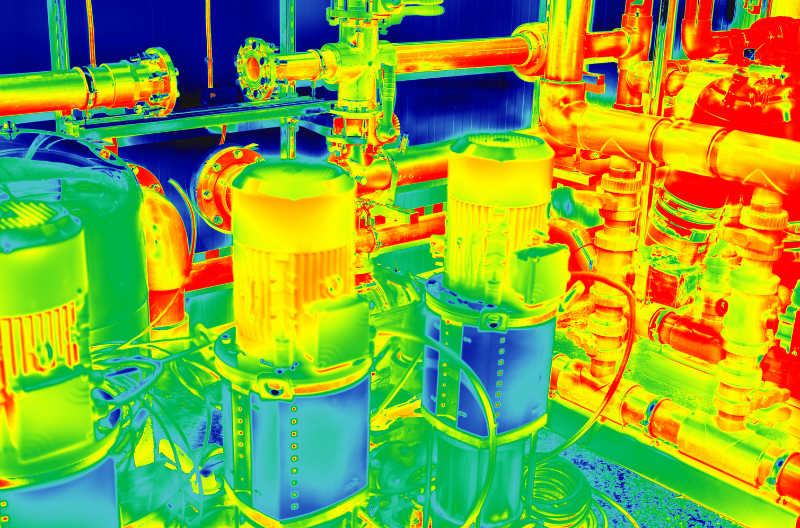

With the evolution of infrared thermography, inspectors can now use special cameras and equipment to see what is invisible to the naked eye. These infrared cameras capture the thermal radiation emitted by anything with a temperature and turn them into colorful images where each hue represents a different temperature. For instance, warmer areas are typically shown in warm colors such as red, orange, or yellow, while cooler areas are represented by cooler colors like blue or green. Thermographers analyze these thermal images to identify anomalies, temperature patterns, or potential issues such as electrical faults, insulation deficiencies, or water leaks.

Infrared Thermography surveys can detect problems and avoid costly fires or floods that lead to property damage and business interruption losses. Here at PLM, we have certified Level-1 Thermographers who are able to help identify problems and take the necessary corrective actions to prevent costly property losses.

Our review of recent fire losses has indicated that the majority have occurred within sawmills, pallet shops, and wood manufacturing operations. Therefore, we are actively completing site surveys and helping to identify elevated temperature exposures – primarily within electrical systems.

By partnering with brokers and customers, a plant facility thermographic scan can usually be completed within a single day. This helps to provide a direct and immediate property loss control strategy.

A recent visual inspection completed for a PLM customer indicated nothing wrong with their electrical equipment. However, after completing a thermographic scan, we identified a problem with their three-phase, low-voltage electrical circuit. Their electrical box was in excess of 400o F and the circuit was in a condition of imminent failure. Prompt action was required to prevent a fire in either the electrical equipment, the production machinery served by the electrical circuit, or both.

PLM’s Loss Control Team recommends having a good electrical maintenance program in place.

- Keep it clean: Dust is a part of our industry, but it needs to be removed from electrical equipment as it can cause overheating and increase electrical resistance.

- Keep it dry: Electric equipment works best in a dry, corrosive-free environment.

- Keep it tight: Vibration and high-speed movement can loosen connections.

- Keep it friction-free: Misalignment of machinery, excessive wear, and failure to lubricate can increase friction.

- Keep it inspected: All equipment should be inspected on a regular and documented schedule, with critical equipment receiving the most frequent inspections and testing. All inspections and testing should be logged and documented.

- Keep it safe: Always follow the manufacturer’s recommendations for maintenance and use a trained and certified electrician to perform work.

To learn more about Infrared Thermography or the IR scanning program at PLM, please contact your local Loss Control Representative or reach out to us at custserv@plmins.com.