We return with the PLM Monthly Highlights series for insurance producers and brokers, our newsletter to keep informed on news and updates from Pennsylvania Lumbermens Mutual. This month, we wanted to get your input with our survey on business classifications and which system you prefer when prospecting new opportunities.

SIC or NAICS? For example, SIC: 5211 Lumber and Other Building Materials Dealers vs. NAICS: 444110 Home Centers / 444190 Other Building Material Dealers

RISK ALERTS – Mobile Equipment Fires

We discussed lessons that can be learned from large losses in our recent Producer Update. One concerning loss trend for some clients are fires around their mobile equipment.

Many businesses in the wood products industry utilize mobile equipment in their daily operations. One of the most common risks associated with mobile equipment, off-road vehicles, and tub grinders are fires. Some of the reasons for these fires are:

- The equipment operate for long durations

- Modern emission control systems require much higher temperatures

- Continuous heat is generated from engines, turbo charges, and brakes

- They utilize flammable liquids, grease, and hydraulic fluids

- Wood dust and chips build up around heat producing components

- The equipment is usually located outside of areas with access to fast fire department response

A fire to a client’s mobile equipment can result in loss of income, equipment down time, and costly repairs. Keeping up with preventative maintenance can help combat fires, however, paired with the addition of a fire suppression system can dramatically reduce the chance of fire to their valuable mobile equipment.

Fire Suppression Systems

There are two types of automatic fire suppression systems — dry and liquid suppression agents. Both can be effective when installed properly and in accordance with manufacturer recommendations. However, for outdoor windy areas, wet-chemical systems are recommended because they are more resistive to dispersion before it is in contact with the fire.

The goal of these systems are to extinguish the fire and cool the components to prevent reignition. The basic system normally consists of one agent storage cylinder. Agent discharge nozzles are strategically located to deliver fire suppression agent to known hazard areas such as turbo chargers, starters, alternators, batteries, hydraulic pumps, and in some cases, vehicle brakes. The system is automatically discharged when the heat detector senses a fire condition in a protected zone. The system can also be manually discharged the instant the operator notices a fire condition. Some additional things to note about fire suppression systems:

- All automatic fire suppression systems should have manual activation controls and be UL Listed or FM Approved.

- Fire suppression systems must be custom designed to your unit. These systems can be cartridge operated or internally pressurized systems. Cartridge systems require routine maintenance every six months to make sure that it will properly function. Pressured systems require in depth inspections every six years. Your manufacturer will detail the inspection and maintenance requirements for your system.

- The equipment operator should visually check the system daily to verify it is operating properly.

- A very effective recent technology is the use of thermoplastic tubing. The tubing is designed to melt and release a fine mist of saline water and AFFF biodegradable, nontoxic foam.

Recent Wins

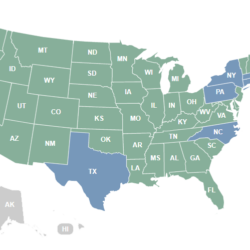

Looking for ideas for new types of risks? Here are some examples of accounts successfully written by PLM or with WC placed through ABM.

PLM Recently Bound Accounts

Wooden Box Manufacturing – CA: $50,000

Lumberyard – OK: $5,100

Custom Closets – CT: $29,000

Building Material Dealer – MT: $8,000

Pallet Manufacturing – MI: $81,000

Cabinet Manufacturing – TX: $11,500

Home Center – IL: $18,500

Lumber Distribution – MA: $9,000

Furniture Manufacturing – NC: $59,000

Moulding/Millwork – LA: $15,000

ABM Recently Bound Accounts

Moulding/Millwork – AZ: $12,200

Wooden Bat Manufacturing – ME: $7,400

Woodworker – MN: $11,500

Pallet Manufacturing – TX: $126,000

Lumberyard – KY: $3,200

Cabinet Manufacturing – PA: $20,500

Commercial CNC Routing – IN: $13,000

Building Material Dealer – TN: $4,900

Hardware Store – MO: $16,000

Cabinet Manufacturing – CA: $26,200

Upcoming Events

Find PLM and ABM at these upcoming insurance conventions and trade show events:

- 8/21 – IIABO – INSURCON Annual Convention – Sunriver, OR

- 8/24 – IIABAZ – Convention & Trade Show – Scottsdale, AZ

- 8/24 – PIANC – Annual Conference – Winston-Salem, NC

- 8/30 – AWIA – Annual Convention & Trade Show – Cheyenne, WY

- 8/30 – IMAGE of Wisconsin – Fall Meeting – Elkhart Lake, WI

BUSINESS HIGHLIGHT – Growing Your Book

In an increasingly competitive and homogenized industry, one of the best ways you can expand your book and differentiate yourself is by entering a specialty market.

Lumber, trucking, marine or other specialty markets offer independent agents the opportunity to diversify their revenue streams and develop competitive expertise, per a recent article written by PLM SVP Steve Firko for Independent Agent Magazine.

Here are three steps independent agents can follow to get started:

- Find a new market: Take a broader view of your current book and segment your current policyholders to see where they are grouped. Beyond current clients, take a deep dive into popular industries operating within your geographical region. Then, consider economic data, national, regional and local trends, as well as specific industry trends, to identify which specialty markets are underserved and could be most advantageous to break into.

- Build a plan: from marketing to training to carrier relationships. Working with a carrier that has an open-brokerage model (like PLM) can be valuable to agents looking to move into a new niche. Other carriers require appointments and may have premium requirements or other commitments.

- Marketing: Formulate a well-defined and researched marketing plan with resources to conduct regular outreach within the industry.

- Training: Research common training and educational opportunities in this new market segment and use these classes as an opportunity to build an understanding of the market.

- Subject matter experts: Build a list of recognized subject matter experts in the segment and study their insights on trends and issues.

- Potential carriers: Make sure you have the right insurance carriers to support expanding your relationships with the new industry segment.

- Build a reputation: by building your knowledge and expertise. If you are considering making the lumber segment your niche, consider carrier loss control guides or accessing resources produced by the Institute for Business and Home Safety and the National Fire Protection Association

Referrals and references are important to expand your reputation and, subsequently, client base. Don’t be afraid to ask for referrals and request introductory meetings from your clients. Odds are your current clients and contacts will be glad to give you references to others and support your efforts.

Attending industry events and joining associations and networks are also great ways to meet key players and industry leaders and make yourself known. However, attend these meetings prepared with insights, including specific risk management or insurance-related knowledge, relevant to these groups. Attendees will quickly see the value of your expertise.

It can take years of commitment and dedication to build a strong reputation and knowledge base in a niche. However, taking the time to research, understand the business and build out a plan can be incredibly rewarding for independent agents looking to diversify and build healthy revenue streams for the future.